Iranian Steel Ingot Market, Producers, Exporters, and Market Players

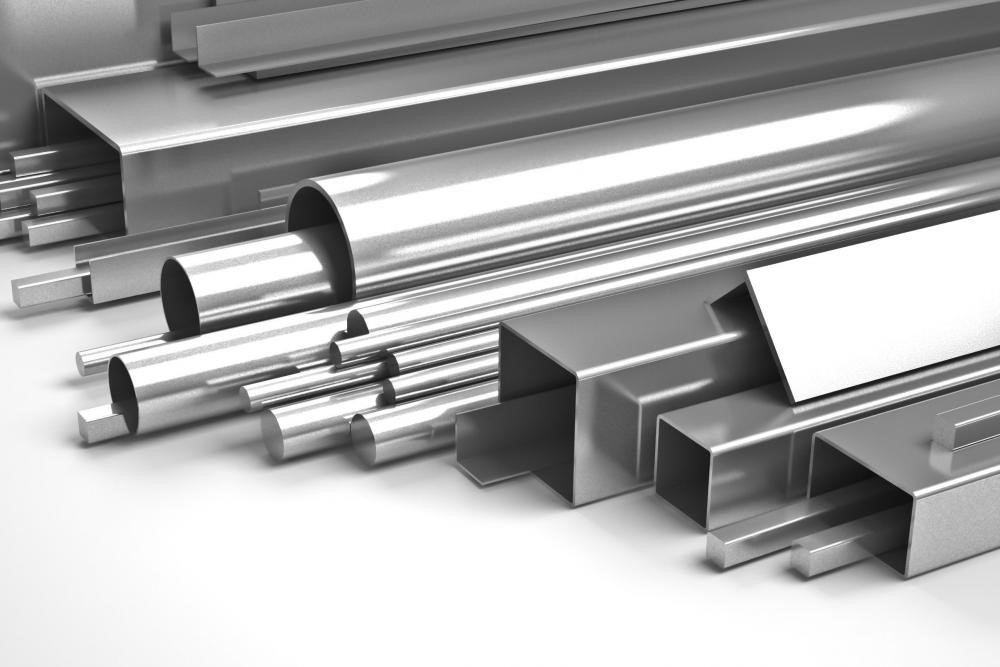

Steel ingot is the first transportable product obtained from steelmaking processes (after iron extraction and raw steel production), which is produced in solid form and in portable dimensions. In fact, the ingot-making process is one of the intermediate processes of steel rolling that produces the raw material for downstream industries. Ingot-making is done by freezing the molten metal in the mold. After converting iron ore into raw steel or sponge iron, after steelmaking and preparation of molten steel in an induction furnace or converter, steel ingot is offered as a prefabricated product with different shapes for different uses. Steel ingots are rectangular pieces whose cross-section is often trapezoidal due to manual molding, ease of removal from the mold, and easy transportation, and the length of each branch reaches a maximum of two meters. This product is generally produced in small workshops.

The Importance of Ingots in the Steel Production Chain

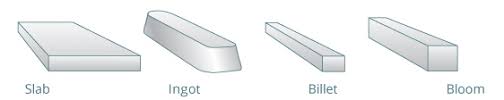

The steel production chain refers to all stages of production of raw materials, intermediate products, semi-finished products, and finally finished steel products. Raw materials include materials such as iron ore, intermediate products include products such as ingots, slabs, billets, and blooms, semi-intermediate products include products such as iron sheets, and finally products include products such as cans, profiles, etc.

Application of Steel Ingot

According to the definition of the position of steel ingots in the steel chain, it can be well understood that the use of ingots is the production of semi-finished products and sometimes final steel products. For example, slabs are used to produce sheet, which is considered a semi-finished product. Of course, there are workshops in Iran that use billets and blooms to produce sheets, but usually, slabs are used to produce iron sheets. They also use billet and bloom to produce sections such as rebar, corner, stud, beam, hash, and all kinds of rails. So, each type of ingot has specific uses.

Types of Ingots

As mentioned before, for the production of each type of steel product, a type of ingot should be used. The products that are produced using ingots are all produced by the hot rolling process. This means that first, the ingots, which previously reach the factory in the form of cast steel parts, are heated in furnaces up to 900 degrees, and are prepared for the production of sections, and hot rolled products. Ingots are mostly classified based on their dimensions.

Slab

Slab is considered the most well-known type of ingot. The width of the slab is significantly larger than its thickness. In fact, this ingot has a flat shape. Clearly, it is considered the best option for producing a product such as steel sheet.

Billet

The billet has a square cross-section. Considering that the sides of the billet are equal, it is considered very suitable for solid sections. When the molten billet passes through the rollers, it can be placed in the most central part of the mold, so that the most molten part of the billet forms the desired section. This makes the mechanical properties of the product evenly distributed throughout the production length.

Bloom

Bloom is an ingot very similar to a slab. However, due to the fact that its width-to-thickness ratio cannot be considered a significant number, it has practically been removed from the classification of slabs. In terms of the shape of the cross-section, it is practically similar to a slab, but in terms of the ratio of width to thickness, it is closer to a billet. This type of ingot is suitable for open sections such as studs and corners.

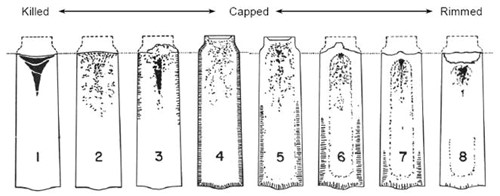

Types of Steel Ingots in Terms of Oxygen Content

The presence of a large amount of oxygen in the structure of steel is harmful because it causes porosity in the structure by combining with carbon and forming carbon monoxide. For this reason, steels need to be deoxidized. Steel ingots are divided into the following types based on the degree of deoxygenation:

Rimmed Steel

This type of steel ingot contains a large amount of oxygen that has not been removed. Because when oxygen is released in the form of carbon monoxide gas, a state similar to boiling occurs in this type of steel, it is also called boiling steel. The amount of oxygen in rimmed steel is about 0.02 to 0.04%, but even this amount is high. In this type of steel ingot, impurities accumulate in the core of the steel and its surface is relatively pure. For this reason, this type of ingot is the best product for the production of car sheets and sheets used in home appliances that are produced under pressing. This type of steel is also used as a welding electrode core.

Semi-killed Steel

In this type of ingot, part of the oxygen has been removed, not all of it. This type of steel has less internal gas and its structure is close to killed steel. In the early stage of semi-killed steel casting, there are no bubbles. When the upper surface of the melt solidifies naturally, due to the enrichment of carbon and oxygen in the molten steel and the decrease in temperature, a small amount of carbon monoxide bubbles is produced in it. Above the ingot, the solidification shrinkage space fills the entire molten steel. Semi-killed steel is mainly used for medium carbon content and medium quality structure, and the mold used for it is generally open type with a small top and large bottom.

Killed Steel

Killed steel is a type of steel ingot that has all oxygen removed and its cross section is homogeneous. The amount of oxygen in the molten steel is so low that it does not react with the carbon in the steel and can’t create carbon monoxide bubbles. Before casting, the molten steel must be sufficiently deoxidized, which can be done using silicon and aluminum. A steel that contains at least 0.1% silicon and at least 0.02% aluminum in its structure is definitely not a welding type.

Common Defects in Types of Steel Ingots

In order for steel ingots to have good structural and surface quality, it is necessary to prevent some defects in them during casting. This is very important in increasing the quality of final steel products. The most common surface and structural defects in steel ingots are as follows:

- Shrinkage holes: Shrinkage holes are created when molten steel shrinks in a steel mold.

- Transverse crack: A type of crack on the surface of the ingot, generally at a shallow depth, which can be removed by fine grinding.

- Longitudinal crack: This type of crack is generally created in the upper part and corner of the billet, which is very deep and difficult to remove by grinding.

- Surface inclusion: Refers to the non-subtractive integration embedded on the surface of the ingot.

- Surface porosity: Refers to small holes that are exposed to the eye on the surface of the ingot and are mostly found in the middle and lower part of the ingot. These pores are generally not deep and can be removed by machining.

- Protrusion: In this case, the upper part of the ingot rises irregularly.

- Pockmark: Scratches on the surface of the ingots.

- Double casting: Clear traces of rejoining around the surface of the steel billet.

- Flash: The metal sheet that is at the head or end of the ingot perpendicular to its surface is called a flash.

- Bubbles: Bubbles are caused by weak degassing and deoxidation of molten steel or wet raw materials.

Applications of Steel Ingots

Steel ingots are not used in the form of slabs, billets, and blooms in their raw form, and they are used to produce final steel products. These ingots are subjected to processes such as rolling, extrusion, and cold drawing, and products with the following specifications are produced through them:

- Belt: A rolled product slab with a width between 20 and 60 mm and a thickness of less than 6 mm;

- Strip: A rolled product slab with a width of less than 20 mm and a thickness of less than 6 mm;

- Plate: A rolled product slab with a thickness of more than 6 mm;

- Sheet: A rolled product slab with a thickness between 0.1 and 6 mm.

- Gold sheet or foil: A rolled product slab with a thickness of less than 0.1 mm.

- Pipe: A rolled sheet product with high diameter and low thickness.

- Tube: A rolled product of sheet, plate, rod, or (billet) with a small diameter and high thickness or a product of tube stretching with a small diameter and thickness.

- Rebar: A rolled product billet or bloom with a diameter between 8 and 40 mm.

- Profile: A rolled product bloom with special geometric shapes such as beams, corners, studs, and railway rails.

To Which Countries Is Iranian Steel Exported?

The best Iranian steel-importing countries are as follows:

- United Arab Emirates

- Italy

- Thailand

- Indonesia

- Afghanistan

- Oman

- Egypt

- Taiwan

- Iraq

- Türkiye

- India

- Sudan

- Jordan

- Belgium

- Spain

Iran's Rank in Global Steel Production

In 2022, Iran was able to take seventh place for the first time by producing 2.9 billion tons of steel. According to the World Steel Association, the growth of Iran's steel production by 3.9% was happened in November 2022, while the world's steel production decreased by 3.7% in November and the amount of steel production in the United States decreased by 10.5%. For this reason and according to the same report, steel production in Iran in November was higher than Germany, which is one of the largest steel producers in Europe. In addition to Germany, the production of Iran has been more than the steel production of Brazil and Turkey. The production of steel in Germany in November 2022 decreased by 17.9% and its amount reached about 2.8 million tons. Also, Brazil's steel production decreased by 16.3% in November 2022 and this amount reached almost 2.6 million tons. Turkey, like Germany and Brazil, has a decrease in production in such a way that it produced 2.4 million tons of steel in November, which is accompanied by a decrease of 30.7%, which is much lower than in previous years. Unlike these three countries, China, India, and Iran were able to expand the amount of steel production and face an increase in steel production in November 2022. So, steel production in China increased by 7.3 percent and its production amount in 2022 reached approximately 74.5 million tons. Also, India's steel production reached 10.4 million tons with an increase of 5.7%.

The Biggest Importers of Steel Ingots in the World

- America

- Germany

- China

- Belgium

- Italy

Iran’s Steel Ingot Exports Statistics

Want to see the Iranian Steel Ingot Export Statistics? Contact us! For the Iranian Steel Ingot export statistics, you will be provided with the information needed in each of the customs clearance regions. Have you been looking for further data and information regarding the Iranian Steel Ingot international and domestic market? Leave all your needs in capable hands.

What Makes an Iranian Steel Ingot Exporter a Potential Partner

In order to start your partnership with an Iranian Steel Ingot exporter, you should make sure that the partner has a valid background in the domestic and international markets. Also, you should make sure that your partner has a legitimate business that you can trust. Iran Consultation Group facilitates all the processes for you by checking the background of your partner and monitoring your relationships. All in all, these are some of the most important characteristics of a good Iranian Steel Ingot exporter as your business partner:

- In-depth experience in exporting Damask Rose

- Owning a successful factory in the field of Damask Rose packing and processing

- Legal Activity

- Owning active Damask Rose farms

- Appropriate Business Behavior

- Experiences in the International Market

- Owning a company outside of Iran for easier international transactions and trades

List of Iranian Steel Ingot Exporters

Looking for the list of Iranian Steel Ingot suppliers and exporters? Contact us and we will provide you with all the required information.

What Do We Do?

Through our years of experience, we have helped companies from various countries find a safe way to the Iranian market. Thanks to our connections and databases, we provide our clients with:

- detailed information and research about Iran’s market based on your proposal

- finds the right partners/cooperators/sellers for you

- arranges business meetings between you and them

- supervises your negotiations

- helps you form a positive relationship

- checks the legal validity of your shared contracts (or forms contracts/MOUs) for you

- helps you with shipping and quality control

- finally facilitates your international settlements

All in all, with Iran Consultation Group beside you, you have a trusted representative office in Iran, that shares the local in-depth knowledge of Iran’s market with you and makes sure you are in the best route of business.

Let’s Request a Schedule For Free Consultation

Contact Us

Willing to cooperate with us? We are always ready to expand! Contact us and we will continue this conversation over a B2B session!

Email: contact@iranconsultation.com

WhatsApp No: +98 901 709 7978

Mobile: +98 901 709 7978

Phone: +98 71 3646 1952